When The Blue Oval unveiled its new universal EV platform last month, that announcement was largely centered around the new and improved production process it will utilize at the Louisville Assembly plant, which will begin building a new mid-size Ford EV pickup in 2027. The automaker touted the fact that it will be able to build vehicles much faster and more efficiently using that process, but as it turns out, the forthcoming retooling will also make life easier on the folks that are assembling the new Ford EV pickup, too.

“We listened to all the things operators don’t like. Safety is our top priority, consistent with what we hear from operators. The result is that their work at Louisville Assembly plant will be significantly more ergonomic. It’s designed to require less twisting, turning and bending,” said Bryce Currie, Ford vice president of Americas manufacturing.

“We want this to be the most efficient plant, assembling the most efficient product in the market,” Currie added. “The vehicle arrives in front of the operator as a kit – with parts in the right orientation, and fasteners, scanners and power tools included in the kit. This helps them focus and keep their eyes forward with limited stock behind them. We’ve engineered an 84 percent reduction in reaching over the fender, as one example. The wiring harness is also more than 4,000 feet shorter and 22 pounds lighter than in our first-gen electric SUV, making it much easier to install.”

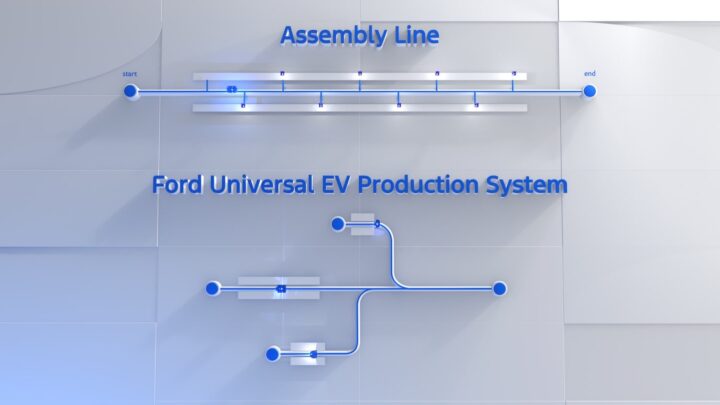

Ford is investing a whopping $2 billion into the Louisville Assembly plant to make this happen. Its new production system is quite a bit different than a regular assembly line in many ways, as it’s laser-focused on improving efficiency throughout that process – largely by transforming the traditional assembly line into an “assembly tree.” This means that rather than utilizing one, long conveyer, Ford will employ three subassemblies running down their own lines at the same time, which then join together. From there, Ford has replaced dozens of smaller parts with large, single-piece aluminum unicastings, which gives it the ability to assemble the front and rear of vehicles separately.

No Comments yet